Kyocera, Japan is one of the leading suppliers of Indexable Cutting Tools in the world today. With its vast range of tools, Kyocera offers practical solutions for demanding and complex machining problems in automotive, die-mold, aerospace, computer parts and heavy engineering industry. Kyocera cutting tools are highly valued for their superior quality and functionality.

|

Cermets |

| |

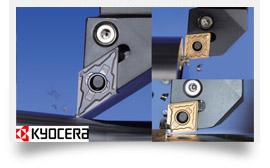

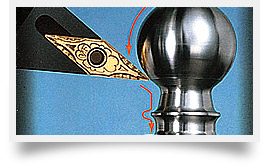

| Kyocera is best known as the leading manufacturer of cermets. Kyocera Cermet inserts come in a wide variety

of grades and designs to provide long tool life and excellent surface finish in turning, boring, threading, grooving and milling operations. Cermet cutting tools combineexcellent toughness with superior wear resistance. |

| |

| |

|

|

| |

|

Ceramics |

| |

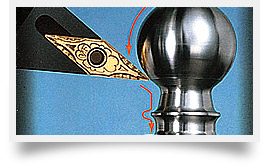

| Ceramic inserts are capable of running at high speeds thus reducing expensive machining times. Ceramics are

ideal for hard turning of carbon & alloy steels, tool steels and cast irons. Kyocera's ceramic inserts offers a preferred replacement to carbides and CBN machining in many instances. |

| |

| |

|

|

| |

|

Small Dia Precision Machining |

| |

| Kyocera's Small & Boring Tools range is among the most comprehensive in the industry. Starting with minimum

bore dia of 2mm, Kyocera offers 3 different options for L/D ratio of 3, 5 & 7. With Kyocera's Excellent & Dynamic

Boring Bars, the use of expensive carbide boring bars can be avoided in most cases. With micro-fine PVD coated

grades, high precision finish is achieved with minimal efforts. |

| |

| |

|

|

| |

|

Turning (General Machining) |

| |

| Kyocera offers wide range of carbide grades with PVD and CVD coating for stable and efficient machining,

ranging from high speed machining to heavy interrupted Cutting. The new coated carbide grades in CA55

series (for steel), CA45 series (for Cast iron) and CA 65 series (for stainless steel) offers superior wear

resistance and results in shorter machining time by high speed and high feed machining. |

| |

| |

|

|

| |

|

Grooving |

| |

| Kyocera offers wide range of grooving tools to meet the growing demands of industry. Ceratip Plunge & Turn

allows grooving and turning operations with same tool. Cermet grooving offers unmatched precision and

surface finish. With MY chipbreaker and 3 cutting edges, greater efficiency and cost reduction is achieved with

minimum efforts. |

| |

| |

|

|

| |

|

Drilling |

| |

| Kyocera's Magic Drill is one of the best indexable drills available in the world today. With its original four

corners-three chips design, Kyocera's drill gives maximum tool life with high quality surface finish. The unique

design of Magic Drill results in very low cutting force and allows drilling on Slant and Concave surface. |

| |

| |

|

|

| |

|

Milling |

| |

| The new generation pentagonal Facemill (MFPN), 4-edges Square Shoulder Endmill (MEW) and 90 degree 6-edges Facemill Cutter (MFWN) are the latest offering for Milling applications in Steel & Cast Iron. The new Megacoat Nano technology results in long tool life at high speed milling due to high hardness and high oxidation resistance. |

| |

| |

|

|

| |

| |

|

|

CBN Inserts |

| |

| Kyocera's new CBN inserts offers the unique advantage of MEGACOAT, Kyocera's patented coating technology.

The Megacoat results in extended tool life and improved stability at high speed machining. The new coated CBN

covers the most demanding hard part machining applications in automotive and general engineering

applications. |

| |

| |

|

|

|